Plane Maker Manual

Last updated:

About This Manual

This is version 12.0 of the manual to Plane Maker. The latest version of the manual will always be available from the X‑Plane Developer web site.

Throughout this text, there will be cross-references to other parts of the manual, as well as hyperlinks to web pages. These will be formatted as blue text. The Table of Contents is also cross-referenced; click on the section you’re looking for to travel there instantly. To search for a specific term or set of words, press “ctrl” (“command” on a Mac) + “f” to be taken to the term anywhere in the document. For a PDF version of this manual, use an HTML to PDF converter such as pdfcrowd.com.

This manual, like all X‑Plane documentation, is released under the Creative Commons Attribution-ShareAlike 2.5 license. This means you are free to copy, share, and adapt the works so long as you give Laminar Research (creators of X-Plane) credit and release your work under a similar license.

Throughout the manual, we make use of images from Wikimedia Commons, a database of some 8 million freely usable media files. The images’ creators we credit do not endorse either Laminar Research (creators of X-Plane) or the manual itself. Instead, they have released the images under Creative Commons licenses, allowing anyone to use the photos so long as they comply with the applicable license.

For the most part, this manual assumes basic knowledge of the X‑Plane user interface-in particular, it assumes knowledge of how to open and fly an aircraft.

The best way to use this manual depends on what you need from it. If you’re already a master of Plane Maker, it probably makes sense to just keep this document around for reference. If instead you’re coming to this manual as a guide for a complete walkthrough to creating your first aircraft, it probably makes sense to read through in this order:

About This Manual (this page)

Working with the Aircraft’s Systems, Section “Creating the Engines”

Modifying an Aircraft’s Properties, Section “Setting the Weight and Balance”

Following the chapter Performing a Test Flight, your aircraft would be at least tested, and you could go back through the sections you skipped as necessary.

We recommend that users consult the Glossary of Terms found at the end of this manual for reference as needed.

Introduction to Plane Maker

Plane Maker is a program bundled with X‑Plane that lets users design their own aircraft. Using this software, nearly any aircraft imaginable can be built. Once all the physical specifications of the airplane have been entered (e.g., weight, wing span, control deflections, engine power, airfoil sections, etc.), the X‑Plane simulator will predict how that plane will fly in the real world; it will model the aircraft’s performance just like it does for X-Plane’s built-in aircraft.

Airplanes are saved in Plane Maker just as one would save a word processing document. These files are then opened and flown in the X‑Plane simulator. Users can create a .zip file of all the components of the airplane and distribute that ZIP on the Internet for others to fly. Planes created by others can also be downloaded and used in the simulator. The fan community X-Plane.org’s “Download Manager” page is a good place both to upload and download these planes.

Note that information on how to add aircraft to X‑Plane can be found in Chapter 4 of the X‑Plane 12 (Desktop) manual.

Licensing of Aircraft Created in Plane Maker

You are free to do whatever you like with the aircraft you create.

You can, for instance, sell your aircraft files over the Internet, or modify other users' aircraft with their permission. If you choose to, you can share the files freely, even with users of the demo version of X‑Plane. You can do whatever you like with the files.

One excellent use for Plane Maker is to create the airplane of your dreams, fly it in X-Plane, and then upload it to the Internet for others to fly. Even better, if a company has an exciting new airplane, they can build in Plane Maker, test fly it in X-Plane, and then put it on the company’s web site for customers or potential customers to download! Anyone that has X‑Plane (or even the free demo) will be able to download the virtual version of the aircraft and fly it. This will serve two purposes. First, it will teach more people to fly the airplane, creating potential customers. Then, it will improve the currency of those that already fly it, creating safer customers.

Of course, Plane Maker can also be used to model an aircraft that you already have and fly every day, helping you to keep up your stick-and-rudder and instrument skills.

An Overview of the Plane Maker Workflow

There are as many different ways to go about working in Plane Maker as there are aircraft designers. The following steps, though, serve as a good workflow sequence to start from when modeling in Plane Maker:

Decide on a design.

Create the fuselage, wings, and tail of the aircraft.

Create secondary objects, such as landing gears and engine nacelles.

Set up the systems and internal properties, including the engines, electrical systems, weight and balance, and viewpoints.

Set up any additional features of the aircraft, such as added weapons or special controls.

Create a 2-D instrument panel.

Test-fly the aircraft in X‑Plane and fine-tune the features of the aircraft from steps 2–6 as needed.

Add textures, 3-D objects, extra liveries, etc.

The Plane Maker Interface

Remember that definitions for any unfamiliar terms may be found in the Glossary. Helpful information has been built into every screen of Plane Maker as well. Hold the mouse pointer over any of the boxes or buttons to bring up an explanation of the setting.

Launching Plane Maker

Plane Maker is installed by default in the main X‑Plane directory. Simply double click Plane-Maker.exe (Plane-Maker.app in Mac OSX) to start the program.

You have the option of editing dimensions in metric units. To change the unit of measure, open the Viewpoint dialog from the Standard menu. In the General tab, click the check box labeled “edit in metric dimensions,” found on the right side of the cockpit information box. Note: Checking this will not alter the unit of measure for thrust or weight.

Opening and Saving an Aircraft

To open an aircraft in Plane Maker, click on the File menu and click Open, per Figure 2.1. There, navigate to the folder containing the .acf file you want to modify, then double click on the ACF, or click once and click the Open button.

To save any changes you have made to the aircraft file, open the File menu and click Save. Any changes you made to the aircraft will be reflected the next time you load the aircraft in X-Plane.

Figure 2.1: Clicking File --> Open

Creating an Aircraft File

To create a new aircraft project, open the File menu and click New. Plane Maker will create a new aircraft with nothing but a cylindrical fuselage. If you click File –> Save As from here, you can choose which folder to save the new aircraft in. Be sure to create the folder first in your file browser (Windows Explorer, Finder, etc.).

The standard place to save aircraft is in the Aircraft directory, located within the main X‑Plane directory. For instance, a VTOL craft created for X‑Plane 12 might be found in the following location:

X-Plane 12/Aircraft/My Custom Planes/VTOL/my new VTOL.acf

However, X‑Plane doesn’t care where the aircraft is located—you could just as easily save the project in the Scenery folder.

When you save your fuselage at this point in the creation process, Plane Maker will display a warning because critical information has not been entered yet. You may proceed through this manual in order by clicking the “Understood” button in the warning pop up after each save. If you would prefer to stop the warning messages, first set the “velocity never exceed (Vne)” as described in the section “Setting V-Speeds and G Limits” below. Next you would need to set the weight by following the section “Setting the Weight and Balance” and how the fuel is distributed in the tank(s) by following the directions in “Configuring the Fuel System.”

Author Details and Basic Information

The “Aircraft Author” window is available for users to input detailed information about themselves and their aircraft creations. You should begin any new aircraft by filling in as many of the fields here as possible.

Figure 2.2: The available fields in the Author dialog

By filling out these fields, you’ll be able to search through your X‑Plane 12 aircraft by name, manufacturer, category (general aviation, airliner, glider, etc.), design studio, and more.

Here you can also mark a plane as viable for user flight only, AI flight only, or both, and opt in to always using the latest experimental flight model with the check boxes.

Working with the Views

Figure 2.3: The 3-D aircraft model in the main Plane Maker window

In the main Plane Maker window sits a 3-D model of the aircraft you’re working on. For instance, Figure 2.3 shows the 3-D model for X‑Plane 12’s Stinson L-5 Sentinel.

You can move the whole aircraft model left, right, up, or down by using the arrow keys on the keyboard. Note that the axes are inverted; press the left arrow to move the model right, press the down arrow to move it up, and so on.

You can use the W, A, S, and D keys to spin and roll the 3-D model around its center. You can use the - and = keys to zoom out and in, respectively. Note that you can zoom in and out or move the model faster by holding down the Shift key while pressing the up, down, left, right, -, or = keys.

Additionally, the settings dialog boxes can be moved around screen, which allows you to view the 3-D model of the aircraft on the opposite side of the screen when it’s wide enough.

Plane Maker can display either the regular, “skinned” view of the aircraft model (where the model looks as it would in X-Plane), or it can display a wireframe view showing the actual structure of the aircraft. To swap between these two views, press the spacebar. Figure 2.4 shows these two views side-by-side.

Figure 2.4: The skinned view of an aircraft, side-by-side with the wireframe view

The wireframe view can be especially useful for telling where exactly a piece of the aircraft is in relation to the rest of the body, and it is the only view in which the points representing the aircraft’s center of gravity, the pilot’s viewpoint, the jet engine locations, and other such features are visible. These are represented as large black dots in the wireframe.

Special Views

The Background menu has a number of special viewing angles that are useful for many designers. These are the Top, Bottom, Side, Front, and Back views, as seen below.

Figure 2.5: The five special viewing angles

Clicking one of these options in the menu will shift the 3-D model to the indicated perspective. For instance, the Top view gives a top-down view of the aircraft, the Side view gives a straight-on view of the craft’s port (left) side, and so on. One potential use for these views is to compare the aircraft model to an image of the real thing. Click the Background Bitmap button in the bottom left corner of the window to load an image to compare your model against.

For instance, if you had a top-down photo of the aircraft you were modeling and you wanted to see how closely your design matched it, you could click the Background Bitmap button, load that photo, and then select the Top view from the Background menu. This will display your Plane Maker model on top of the real aircraft’s photo, centered on the screen.

Altering a Simple Aircraft

To familiarize yourself with the workings of Plane Maker, it may be helpful to begin by tweaking a simple aircraft. The Boeing 777 from older versions of X‑Plane is a good option. You can download a zip file of the aircraft here to follow along in the following examples.

Use the File menu to load the basic aircraft of your choice, then open the Standard menu and click Wings.

When the dialog box opens, click through the tabs labeled Wings 1–4 at the top of the dialog box. Different sections of the aircraft model’s wings will flash. (This will be easier to see if your window is wide enough to display a secondary aircraft model off to the right. Additionally, it will only work if the wings have not been made invisible, in the Invisible Parts dialog box of the Expert menu.) The section of wing that flash is the section that the current tab controls. In the case of the 777, wing sections 1, 2, and 3 comprise the full wing.

Try selecting the Wing 3 tab. This selects the wing section farthest from the fuselage of the 777. Now, there are a large number of ways to modify the wing here. We’ll discuss each of them in Chapter 3, but for now, find the “semi-length” value, found in the box labeled Foil Specs. Try clicking above and below the digits here to lengthen and shorten the wing segment. For instance, in Figure 2.6, we’ve lengthened the wing segment by about 20 feet.

Figure 2.6: Lengthening the wings of the 777

If we were to save this file (as a copy, of course, so that we did not modify the original 777 file) and fly it in X-Plane, we would find that the wings generate significantly more lift, but they also make the aircraft much less maneuverable (functions of having a high aspect ratio).

Taking a step back, this example is useful because it demonstrates a very common interface in Plane Maker. In the Foil Specs portion of the Wings dialog box, we have a number of properties of any given wing, each of which can be set individually and which combine to give a complete wing.

Note also that you can move the mouse over almost every input field in Plane Maker and get a description of what that field controls. Don’t know what the sweep field does? Mousing over the numbers in the input field reveals the following description:

The sweep is the angle that the wings are swept back from sticking straight out the side of the airplane. Wing sweep is used to allow high-speed travel (above Mach 0.7 or so), because the wing does not have to attack the air head-on.

Pretty informative, right? If you are ever unsure of what a parameter controls, mousing over it is a good way to get help.

Shaping the Body of an Aircraft

In this chapter, we’ll look at the things that constitute the body of an aircraft, including the fuselage, tail, landing gear, wings, and airfoils. These represent the core of almost every aircraft design.

Note: You can change the unit of measure in the Default tab of the Viewpoint dialog box, found under the Standard menu. Check the box “edit in metric dimensions” if you would like to edit the dimensions of your aircraft in meters.

Fundamental Concepts

A few ideas will come up over and over again throughout the creation of an aircraft body. The first is the concept of the reference point, and the second is the way in which positions in Plane Maker are set relative to the reference point. Understanding these two things ahead of time will make learning the specifics of creating the fuselage, wings, and other objects much faster.

The Reference Point

All objects (the fuselage, wings, etc.) in Plane Maker are placed relative to some arbitrary fixed point, called the reference point. This point is created simply through use. For instance, you might tell Plane Maker that your plane’s fuselage (and, in particular, the front tip of your plane’s fuselage) is located at the reference point—it is zero feet away from it, angled zero degrees away. Likewise, your wings might be located ten feet behind the reference point, angled a few degrees back.

On its own, this point doesn’t mean anything—it’s just some place on the aircraft that everything else gets its location in relation to. While the point could be anything, you should choose a point that makes sense to you. Some aircraft designers prefer to make their reference point the center of the fuselage, while others prefer to make it the tip of the nose.

How Positions Are Set in Plane Maker

As we have said, all locations in Plane Maker are defined relative to a fixed, arbitrary point, often the tip of the fuselage. However, there is more to defining the position of, for instance, a wing than to say that it is five feet behind the tip of the fuselage. How high above the tip of the fuselage is it? How far left or right?

This is where Plane Maker’s position settings come in. Figure 3.1 shows the three standard controls for an object’s position.

Figure 3.1: A standard position-setting group of parameters

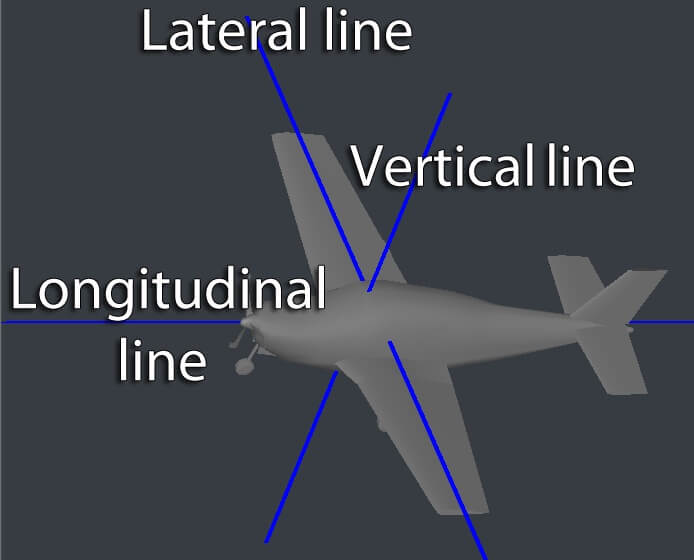

The standard position parameters throughout Plane Maker are the longitudinal arm, the lateral arm, and the vertical arm, as illustrated in Figure 3.2. Each measurement is in relation to the reference point.

Figure 3.2: The three axes used to position an object on the aircraft

The table below gives a reference for interpreting what the values in these positional controls mean. For instance, a positive value in the “vert arm” parameter indicates the object will move above the reference point by that many feet.

| Parameter | Positive value means… | Negative value means… |

|---|---|---|

| Longitudinal arm | Behind reference pt. | Forward of reference pt. |

| Latidudinal arm | Right of reference pt. | Left of reference pt. |

| Vertical arm | Above reference pt. | Below reference pt. |

Interpreting the position-setting values

Note that in cases where an object has lateral symmetry (that is, it is duplicated on both sides of the aircraft, as a wing section is), the guidelines in the table above apply to the object on the right (starboard) side of the aircraft. Likewise, the lateral arm value is reversed for the object on the left (port) side. Thus, a positive lateral arm value for a certain wing section means the right wing section will move right of the reference point, while the left wing section will move left of the reference point.

Shaping the Fuselage

To begin work on a fuselage, open the Standard menu and click Bodies, and if necessary, click on the “Body 1” tab.

Figure 3.3: The tabs across the bottom of the Bodies tab rows

There are five tabs across the bottom row of tabs, seen in Figure 3.3. In order, these are Section, Top, Side, Bottom, and Front/Back. Each tab serves a different purpose. The Section tab displays a cross-section view of the fuselage, sliced into a number of pieces. The Top/Side/Bottom tabs show three different perspectives of the points defined in the cross-section view, allowing you to see their relation in three-dimensional space. Finally, the Front/Back tab shows the same points of the fuselage from a head-on on perspective; this is like looking down the nose and tail, respectively, of a wireframe model of the aircraft.

In creating a fuselage, it makes sense to take the following approach (note that the parameters mentioned below are discussed in the following sections, which dive into each tab in depth):

Begin in the Section tab and set the number of stations (usually 20), the number of radii per side (usually 9), and the body radius.

Referencing whatever specifications you have for your fuselage (this may just be an image of it), set a rough outline of its shape in the cross-sections of the Section tab.

Still in the Section tab, move those rough cross-section shapes to the appropriate distances above or behind the reference point.

Go to the Top/Side/Bottom tabs and drag the points around in three dimensions, possibly with reference to a background image.

Alternate between the tabs to fine-tune the shape.

The Section Tab

In the top-center of the Section tab’s window is a checkbox labeled “aircraft has Body 1.” By default, this box is checked; if the aircraft is a flying wing or another such oddity, it may need to be unchecked. All aircraft will have at least one body; if more are needed, select the next unnamed tab and check the “aircraft has Body” box and continue with the steps below.

If you need to use the shape data from another file, you can use the button labeled Import Aircraft Body. This will set the fuselage shape based on data from another aircraft.

You can save a description of the body (or some other note about it) in the text box mid-screen labeled “part description.”

Aside from these miscellaneous controls, the Section tab has four main divisions. These are the Body Setup box, the body location box, the Body Texture box, and the Cross-Sections box, described in the following sections.

The Body Data Box

Figure 3.4: The Body Setup portion of the Section tab

The Body Setup portion of the window, seen in Figure 3.4, controls the basic features of the fuselage. It is, effectively, your first stop when designing a new fuselage. The “number stations” field sets how many individual cross-sections Plane Maker will link together to form your aircraft’s body. In most cases, setting this at the maximum of 20 is not a bad idea, as each additional station will allow you greater control over the body’s shape. In any case, you will probably want to add 2 to the number of sections you had in mind to account for the fuselage’s two closed ends. For instance, if, when looking at the body, you saw 13 “real” divisions, you would input 15 stations here: 13 “real” sections, which meet at a point at the nose and tail, for a total of 15.

The “number of radii/side” value sets the number of points used in each half of the cross-section. Unless your aircraft has a very simple shape to its body, you’ll probably want to use the maximum of 9; this will allow the smoothest curves possible on the body.

The “grid radius for body” setting controls the width of the cross-section views in the bottom half of the window. For the greatest accuracy when placing the points that make up the body, this should be set to the actual maximum radius of the fuselage. You should, however, err on the side of setting this too high so that all your points are visible.

The “area rule ratio” field should be left at the default (1.0) for most aircraft. If your aircraft is carefully area-ruled, you may enter a smaller number here to reduce the drag of the body at transonic and supersonic speeds.

The final setting in the Body Setup section, labeled “body coeff of drag,” is the body’s coefficient of drag based on its frontal area. This determines the amount of drag generated by the fuselage. An average fuselage will have a coefficient of drag of 0.1, while a very sleek one will have a coefficient of 0.025.

The Body Location Box

The center box of the Bodies dialog box controls the fuselage’s location. Here you can copy the geometry from another existing body, or attach the body to the engine or gear if desired.

The three standard location controls (“long arm,” “lat arm,” and “vert arm”) specify the point in space of the front tip of the fuselage. See the section Fundamental Concepts above for an explanation of these three controls.

Figure 3.5: The Body Location controls

Since all measurements of location in Plane Maker are relative to the reference point, the fuselage position could be anything—the rest of the aircraft just has to be positioned accordingly. Many aircraft designers, though, prefer the reference point to be the front tip of the aircraft. In this case, the fuselage’s location will be zero feet offset from the reference point.

In addition to the standard location controls, the Body Location box also contains directional controls. These are in the form of the heading, pitch, and roll offset parameters. The table below lists the interpretations of these values. For instance, setting a negative value in the heading offset will cause the fuselage to pivot to point left; when seen from above, the fuselage will pivot counterclockwise however many degrees are input here.

| Parameter | Positive value means… | Negative value means… |

|---|---|---|

| Heading offset | Pivots to point right (starboard) | Pivots to point left (port) |

| Pitch offset | Pivots to point up | Pivots to point down |

| Roll offset | Rolls right (to starboard) | Rolls left (to port) |

Interpreting the direction-setting values

In the vast majority of aircraft designs, it makes sense to think of the fuselage as the center of the aircraft, so these parameters will not be used.

The Body Texture Box

The Body Texture box is used for fine-tuning the painted texture on the aircraft (alternately known as a skin or a livery). For information on working with paint textures on the aircraft, see Modifying the Appearance of an Aircraft. For information on the parameters found in this box in particular, see the section of that chapter titled Fine-Tuning a Paint Job.

The Cross-Sections Box

The Cross-Sections box shows slices of the aircraft’s fuselage. There is one slice of the fuselage for the number of stations set in the Body Setup box, each slice in a gridded, white box, as seen in Figure 3.6. Each of these slices is composed of the number of points you specified in the “number radii/side” parameter in the Body Data box (see the section The Body Data Box above for more information on this). Since most designs warrant the maximum of nine radii per side, each of your slices will probably be composed of nine points.

Figure 3.6: The Cross-Sections box

When building your model, Plane Maker will stitch these slices together, so all the cross-sections together will form a complete aircraft body.

We’ve been referring to each of the gridded white boxes as containing a “slice” of the fuselage. In reality, they each contain a half-slice. The nine points (or however many radii/side you have set) seen here compose the right side of a slice; they will me mirrored by another nine points on the left side, for a total of eighteen (or so) points to compose a “full” slice.

Let’s dissect each cross-section view—each “station”—in detail.

At the top of each station is an input field controlling how far behind the reference point this particular slice will be. For instance, in the example cross-section of Figure 3.7, the slice is located 6.1 feet behind the reference point (indicated by the box labeled 1 in the image). Thus, in an aircraft whose reference point is the tip of the nose, this section would be about 6 feet from the nose. Of course, a cross-section could have a negative value here and be moved in front of the reference point.

Figure 3.7: A single cross-section view, or "station"

Remember that Plane Maker will stitch your cross-sections together in the (left-to-right) order that they appear in this box—even if the distances from the reference point that you set in this box do not always increase from left to right. In this way, you could have a fuselage that overhangs itself, or curves inward in some way.

The gridded white box, labeled 2 in Figure 3.7, is the cross-section box itself. Click any point and drag it to reposition it and thus to reshape this slice of the fuselage. Double click on a point to lock its position, protecting it from being smoothed. (Note that smoothing operations are described in the section “Smoothing the Fuselage” below.) Locked points are represented as filled in white boxes in the cross-section view.

Sometimes in the course of editing these cross-section points, it may be useful to zoom in and out or move the cross-sections around. You can zoom using the - and = keys, and you can move the sections using the left, right, up, and down arrow keys. This does not affect the model itself; it only changes the view of the model in editing.

The left and right arrows beneath the cross-section box (labeled 3 in Figure 3.7) are used to copy a cross-section as a whole into the station to the left or right, respectively. This might be useful if you added a new station after working on the stations you already had. In this case, you would start with the farthest right of the stations you had previously worked on and press the right arrow. Then, you would move left and keep pressing the “copy to the right” button, stopping when you got to the place in the station order that you needed a new one.

The “C” & “P” buttons (labeled 4 in Figure 3.7) copy or paste, respectively, the cross section into any other station. Finally, the “O” button (labeled 5 in Figure 3.7) makes the station into a circle.

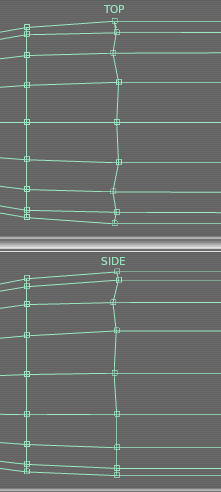

The Top/Side/Bottom Tabs

The Top/Side/Bottom tabs of the Bodies dialog box displays the fuselage’s cross-sectional “slices” stitched together in three different views; that is, it shows the top, side, and bottom views of the complete fuselage formed from the cross-sections. (Recall that these cross-sections may initially be laid out in the Section tab, described in the preceding section of the manual.)

To shape a station, simply click the radius points that make it up and drag them around. Just like in the Section tab, you can double click a point to lock it, preventing future smoothing operations from moving it on it.

The standard movement controls (the up, down, left, and right arrows, as well as the - and = keys for zooming) all operate as you would expect in this window, allowing you to zoom in or out and shift your view around.

Now, how do these three views (top, side, and bottom) fit together? It all starts with the side view—the left side view, in particular. The points that make up the left side are mirrored on the right, similar to the way the half-slices of the Section tab’s cross-section view are mirrored to form a complete slice. The middle, roughly horizontal line in the side view corresponds to the top- and bottommost lines in the top and bottom views.

The views are mirrored in their upper and lower halves; dragging a point in the upper half of the top view will drag its corresponding point in the lower half of that view (in addition to dragging the same point in the side view). They are mirrored like this because the left side view itself is mirrored on the right; thus, the top view, for instance, shows the top half of both the left and right sides.

At the top of the window are two buttons, Reset this section to vertical and Reset all sections to vertical. Often in the course of editing the points of a fuselage, the points of a given section will get out of alignment purely by accident, due simply to the inaccuracy of using a mouse. That’s where these buttons come in. For instance, in the example fuselage in Figure 3.8, you might want to click the Reset all sections to vertical button, thus lining up the points in each cross-section.

Figure 3.8: A situation where the "reset to vertical" buttons are useful

However, in some cases, it is desirable to not have all your sections vertically aligned. In this case, if you still wanted to align the out-of-whack section seen in Figure 3.8, you would need to first click one of the points in the section you wanted to align. Then, after you have effectively told Plane Maker which section you want to modify, you would click the Reset this section to vertical button.

At the bottom of this window are buttons to load an image, clear it or zoom. This can be quite useful for laying out your points properly. For instance, you could take two scale drawings of your aircraft (one to be used in both the top and bottom views and one to be used in the side view) and drag the radius points to match up with this image.

Figure 3.9: Using scale drawings to lay out the points of a fuselage

For instance, in Figure 3.9, we cut up two scale images to be the same size, with the center of the image corresponding to the center of the fuselage, and loaded the images into Plane Maker. From there, we simply dragged the outermost points (or uppermost points, as the case may be) to match the edges of the fuselage in the image. Following that, we dragged the inner points to match the known shape of the fuselage.

The Front/Back Tab

The Front/Back tab of the Bodies dialog box contains two views of the cross-section, front and back. The front view shows the first twelve stations (if there are twelve stations to show) as though you were looking down the nose of a wireframe fuselage model. The back view, on the other hand, shows the last ten stations (again, if there are ten stations to show) as though you were standing at the tail looking down the wireframe model.

The standard movement controls (the up, down, left, and right arrows, as well as the - and = keys for zooming) all operate as you would expect in this window. Using the arrow keys, you can move the wire model over to view the whole fuselage, too, instead of just a half.

The radius points displayed in both these views operate just like the ones in the other two tabs. Simply click a point and drag it to change the fuselage shape there. You can also double click a point to prevent it from being changed in a future smoothing operation (described in the section “Smoothing the Fuselage” below).

The buttons Reset this section to vertical and Reset all sections to vertical are available in this tab as they are in the Top/Bottom tab. However, it may be wise to confine your use of them to the Top/Bottom tab, as you will not be able to see its effect in this view—the view is essentially without perspective, so a point that is far away looks the same as a much closer point with the same up/down and left/right position.

Smoothing the Fuselage

To smooth the fuselage into an elliptical shape, use the “Ellipse-Smooth Fuselage” option (or F1 key), located in the Special menu. The more times this option is used, the closer the fuselage will get to a perfect ellipse.

Adding Other Bodies to the Fuselage

Some aircraft have odd protrusions (such as a large fuel tank poking out from under the fuselage) or even special physical objects attached to them. In this case, it may be best to model the fuselage itself as not having these things. Instead, you might model these things as separate “bodies” (physical objects) which intersect the fuselage. X‑Plane doesn’t care whether the large protrusion on the underside of the aircraft is actually part of the fuselage or just another object touching the fuselage; it will model the aerodynamics the same way.

In this case, you would model the other things using the additional blank “Body” tabs in the Bodies window. To add a new body, simply click on one of these tabs and check the box labeled “aircraft has body,” as seen in Figure 3.10. You can add up to 38 additional miscellaneous bodies in this way.

Figure 3.10: Checking the "aircraft has body" box

Each body is modeled almost identically to the fuselage; there is a Section, Top, Side, Bottom, and Front/Back tab for each body, just as there is for the fuselage. Be aware of the Insert button, located between stations in the Cross-Sections box. Clicking this button will insert a new station between the stations on the left and right sides of the button. Note that you can only use the Insert button when you have fewer than 20 stations.

Shaping the Wings

Wings in Plane Maker are composed of individual wing sections. A very simple wing might be made up of a single wing section, while a very complex wing might be made up of four or more wing sections. Each wing section can have control surfaces added, such as ailerons, elevators, or flaps. Furthermore, each wing section can have its cross-sectional shape (its airfoil) set independently of other sections.

Setting the Basic Features

To create and modify wing sections, open the Wings dialog box from the Standard menu.

The Wings dialog box houses a number of tabs whose contents all look identical. The only difference between them is that, whereas the tabs labeled “wing” and “horizontal stabilizer” control two identical wing sections mirrored on either side of the fuselage, the tabs labeled “vertical stabilizer” control only a single wing section.

When you click on any of the tabs, you will see three boxes in the window: the Foil Specs box, the texture fine-tuning box, and the Element Specs box.

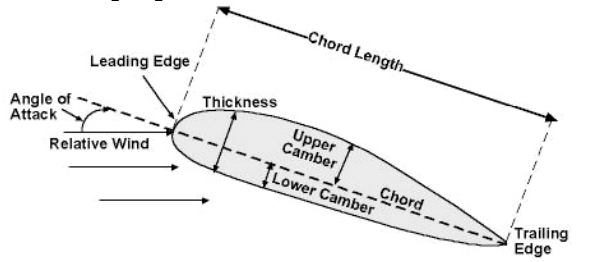

The Foil Specs box controls all the basic properties of a wing section. All wing sections have the following properties:

a semi-length, the length of the wing section from its root to its tip when measured 25% of the way back from the wing’s leading edge,

a root chord length, the width of the wing section where it is closest to the fuselage,

a tip chord length, the width of the wing section where it is farthest from the fuselage,

a sweep angle, the angle backward or forward that the wing is pointing (when viewed from above),

a dihedral angle, the upward or downward angle of the wing section relative to horizontal, and

a location.

Figure 3.11 shows the foil specifications not including the location controls; for information on using the standard location controls, see the section “How Positions Are Set in Plane Maker” at the beginning of this chapter.

Figure 3.11: The foil specification parameters

In most cases, a wing is composed of more than one wing section. In this case, you could specify the location of the outer wing sections manually so that they meet up with the next sections closest to the fuselage. However, in the upper right corner of the dialog box is a drop-down menu labeled “snap to,” as seen in Figure 3.12. To snap a wing section to another one—that is, to have Plane Maker automatically align the root of the section you’re applying the snap to with the tip of the section you choose—simply click the drop down button and click on the wing section to snap to.

Figure 3.12: The "snap to" drop-down menu

To the right of the Foil Specs box is the texture box, used for fine-tuning the painted texture on the aircraft (alternately known as a skin or a livery). For information on working with paint textures on the aircraft, see Chapter 8, Modifying the Appearance of an Aircraft . For information on the parameters found in this box in particular, see the section of that chapter titled “Fine-Tuning a Paint Job.”

The Element Specs box in the bottom half of the window determines where ailerons, elevators, flaps, or other control surfaces go on the wing surface.

Adding Ailerons, Flaps, and Other Control Surfaces

To add control surfaces like elevators, rudders, ailerons, or flaps to a given wing section, you must tell Plane Maker where you want each control surface on the wing and you must define the control surfaces themselves. The first part is done using the Element Specs box found in the Wings dialog box, while the second part is done in the Control Geometry dialog box, launched from the Standard menu. The order in which you do these does not matter; do them in whatever order makes the most sense to you.

For our purposes, we will start off in the Control Geometry dialog box. The only thing to be concerned with in this dialog box, at least until after the first test flight, is the Controls tab.

In the Controls tab, a number of possible control surfaces can be created, from ailerons to elevators to rudders to speedbrakes to flaps. Each of these works in a similar way. The left half of the window, in the box labeled Control Sizes, sets up ailerons, elevators, rudders, roll spoilers, drag rudders, and speedbrakes. The right half of the window, labeled Flap Specs, sets up flaps and slats only.

Specifying Ailerons, Elevators, and Other Surfaces

The left half of the Control Geometry’s “Controls” tab is labeled Control Sizes, and it is used for all control surfaces except the flaps and slats.

Figure 3.13 shows the parameters to specify a single control surface (namely, an aileron). There are four input fields here. On the far left is the control surface’s root-side width, as a decimal part of the chord length of the wing section it is placed on. Thus, if this root width were set at 0.50 and it were used in a wing whose root was 5 feet wide, the control surface would have a width of 2.5 feet on the side closest to the fuselage.

Figure 3.13: A single, representative control surface specification

To the right of the root width is the tip width, also specified as a decimal part of the wing it is placed on. So, if the tip width were set at 0.1 and it were used on a wing whose tip was 10 feet wide, the control surface would have a width of 1 foot on the side farthest from the fuselage.

These two parameters, root and tip width, function identically on all the control surfaces available.

To the right of the two size parameters are the fields controlling how far the surface can move, measured in degrees. For instance, in the aileron of Figure 3.13 these are, from left to right, how far down the aileron can deflect and how far up it can deflect.

Specifications for ailerons, elevators, and rudders all follow this same pattern: parameters for the root and tip width, followed by parameters for the maximum deflections. The roll spoilers and drag rudder are exceptions to this pattern. They move one at a time, and they only move upward. For this reason, they have only one parameter for maximum deflection.

Additionally, the speedbrake may have two maximum deflections: one for normal, in-flight operation, and one for ground use. Unlike the other control surface types, speedbrakes don’t have to be mounted to a wing—they can also be mounted directly on the fuselage (or anywhere else, for that matter). For information on doing this, see the section “Adding Body-Mounted Speedbrakes” below.

At the right side of the Control Sizes box is the “control surface type” setting, which modifies how effective the surfaces are in X‑Plane. Surfaces which are “corrugated with gaps” are least effective.

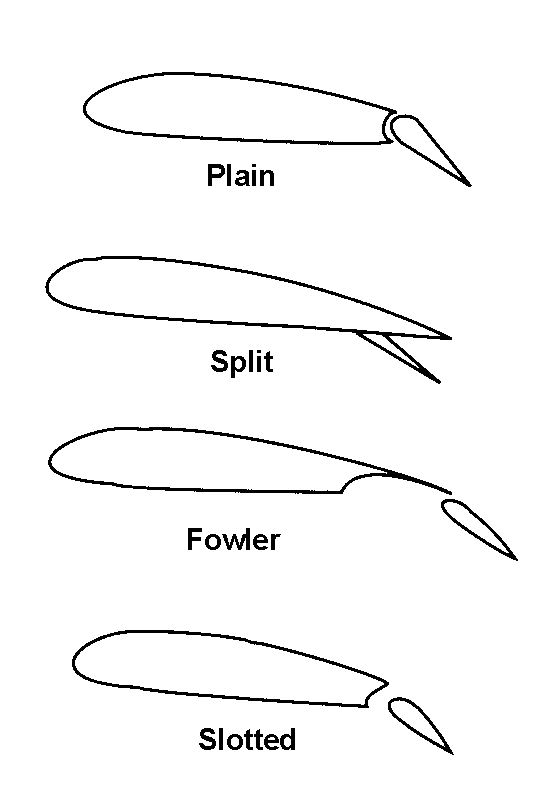

Specifying Flaps and Slats

The right half of the Control Geometry’s Controls tab is labeled Flap Specs, and it is used to set up the aircraft’s flaps and slats.

Let’s walk through the settings here.

Slats change the lift characteristics of a wing. They allow a higher angle of attack for the wing, resulting in a lower stall speed. Two slats can be set up for each aircraft. Using the parameters seen in Figure 3.14, you can set the type of slat—either true slats or Krueger flaps. (Note that Krueger flaps are not technically slats. They deploy by hinging forward from the wing instead of sliding from the top of the wing’s leading edge like slats do.)

Figure 3.14: The "slat type" and "increase in stall angle" settings

Next to the “slat type” control is the “increase in stall angle from leading edge device deployment” parameter, seen in Figure 3.15. Slats work by allowing the wing to go to a higher angle of attack without stalling—that is, without losing lift. Slats in the real world allow the wing to gain up to eight degrees of angle of attack without stalling.

Figure 3.15: The flap type and size settings

Like slats, flaps alter a wing’s lift characteristics. They allow the wing to generate a given amount of lift at a lower speed, resulting in the aircraft stalling at a lower speed. Two flaps can be set up for each aircraft. Using the parameters shown in Figure 3.15, you can set the type of flap, chosen from a large number of options. Each type of flap has unique lift, drag, and moment characteristics, as described in the dark gray box below the flap type setting. Four types of flaps available in X‑Plane are illustrated in Figure 3.16.

Figure 3.16: Four types of flaps illustrated

To the right of the flap type setting are the two parameters controlling the size of the flaps. Just like when setting up ailerons, rudders, and elevators, you must specify the flap size on both the root side and the tip side. These are set as a decimal part of whatever wing section the flap is placed on.

Beneath the flap type and size settings are the parameters that control the aerodynamic coefficients for each flap, as seen in Figure 3.17. Plane Maker will automatically estimate the coefficients of lift (Cl), drag (Cd), and moment (Cm) based on flap size and deflection, but these may be modified manually as well.

Figure 3.17: The flaps' aerodynamic coefficients

If you find that the real aircraft slows down more than X‑Plane predicts when flaps are lowered, you may want to increase the flaps' drag coefficient, perhaps by about 0.01. If, on the other hand, you find that the real aircraft gives a lower stall speed than X‑Plane predicts when the flaps are lowered, you may want to increase the flaps' lift coefficient, perhaps by about 0.1. If you find that the real aircraft does not pitch up or down like it does in X‑Plane when the flaps are lowered, you may need to increase or decrease the coefficient of moment. Decrease the flaps' Cm by, say, 0.1 to pitch down more (or to pitch up less, as the case may be).

In the Flap and Slat Deflections section, you can set the deflection time as well as the detent (or stop-point) characteristics for both the flaps and slats, as seen in Figure 3.18. The flap deflection time is critical for getting proper pitch characteristics when the flaps are lowered.

Figure 3.18: The flap and slat detent characteristics and deflection time

The flap (or slat) extend and retract time parameter, as seen in Figure 3.18, sets the amount of time in seconds that it takes the flaps (or slats) to go from fully retracted to fully extended.

Checking the box labeled “flaps are infinitely adjustable between detents” allows a pilot in X‑Plane to hold the “flaps up” or “flaps down” button to select any flap setting, not just the ones at the detents. Even for aircraft with infinitely adjustable flaps, though, it is still useful to set the detents below, as they will be used in the maximum allowable flap deployment speeds. (Note that the max allowable speeds are set in the Viewpoint menu, as described in Chapter 4, in the section “Configuring Instrument Performance Ranges, Display Limits, and Colors”)

To the left of the “flaps are infinitely adjustable” checkbox is the number of flap detents (as seen in Figure 3.18). A detent is a stopping place for the flaps, a middle-of-the-road between being totally retracted and totally extended. General aviation aircraft might have only one or two stopping points, while airliners might have many more.

Finally, beneath the number of detents are the detent parameters themselves—one set of detent boxes for each flap and slat. Each box sets the flap/slat deflection in degrees at that detent. Note that there is one more box here than the number of detents you set above. This is to account for the “zeroth” detent, which in most aircraft will be a flap deflection of zero degrees.

For instance, in in Figure 3.18, six flap detents were set. Thus, there are seven boxes for “flap 1,” four boxes for “slat 1,” and so on.

Adding Control Surfaces to the Wings

With the control surfaces (elevators, ailerons, rudders, flaps, etc.) all set up in the Control Geometry dialog box, as described in the sections above, it’s time to actually add those control surfaces to the wings. You will need to set the control surfaces individually for each wing section.

To do this, open the Wings dialog box from the Standard menu. In the bottom half of each wing’s tab is a box labeled Element Specs, as shown in Figure 3.19.

Figure 3.19: The Elements Specs box, specifying the control surfaces of a wing section

Highlighted in red in Figure 3.19 is the box controlling the number of pieces that the wing section will be broken into. The wing section will be divided into this many pieces of equal size.

These pieces serve a couple of purposes. First, they represent the divisions of the wing on which X‑Plane will calculate forces for its flight simulation. The simulation works by breaking the wing into pieces, calculating the forces on those pieces, and summing the forces on all the pieces in order to move the aircraft as a whole.

These pieces also serve as divisions across which control surfaces are stretched. For instance, in Figure 3.19, the middle four pieces (and thus the middle half of the wing section as a whole) will have the “flap 1” on them. Likewise, the last two pieces (and thus the final quarter of the wing section, moving from root to tip) will have the “aileron 1” on them.

This brings us to the next feature of the Element Specs box. Highlighted in orange is a single control surface (the “flap 1”), with the boxes checked corresponding to the pieces of the wing section that it is present on.

We have said that the wing section is broken into a number of equal-sized pieces. These pieces are represented here, from left to right, from the root to the tip of the wing section. Thus, when the checkbox on the far left is checked, it means the piece of this wing section that is closest to the fuselage has that control surface. This means that in Figure 3.19, the four pieces in the middle of the wing have flap 1.

Check each of the boxes for the control surfaces that a wing section has. (Note once again that these boxes will only actually do something to the wing if the control surfaces have been set up as described in the sections “Specifying Ailerons, Elevators, and Other Surfaces” and “Specifying Flaps and Slats” above.)

It may be useful when deciding how many pieces of the wing section a given control surface takes up to use the “Show with still/moving controls” option from the Special menu, as shown in Figure 3.20. This will cause Plane Maker to move all the aircraft model’s control surfaces, so you can see immediately where the surface extends to.

Figure 3.20: Show the aircraft with moving control surfaces

Adding Body-Mounted Speedbrakes

Speedbrakes may be added to an aircraft in one of two ways. The first, and most common, is to specify them in the Controls tab of the Control Geometry dialog box, as described in the section “Specifying Ailerons, Elevators, and Other Surfaces” above. However, you can also add them directly to an aircraft’s body (its fuselage, wings, etc.), placing them using the standard Plane Maker position controls.

Body-mounted speedbrakes like these are created in the Speedbrakes tab of the Control Geometry dialog box. Up to four body-mounted speedbrakes can be added to an aircraft using this tab; there is one box per speedbrake, as seen in Figure 3.21.

Figure 3.21: The four boxes for creating body-mounted speedbrakes

Since each speedbrake is created in the same way, we will look at the parameters for creating a single speedbrake.

Start by selecting the speedbrake’s type. The drop down box labeled 1 in Figure 3.22 selects a type of either “none” or “body mounted.” Any speedbrake box that you are not using should have a type of “none” set for it. Likewise, if you do intend to use a body-mounted speedbrake, set its type to “body mounted.”

Figure 3.22: The controls to create a single body-mounted speedbrake

After turning on any body-mounted speedbrakes you want to use, it makes sense to jump down to the geometry box, labeled 5 in Figure 3.22. Speedbrakes in X‑Plane are 2-dimensional, composed of up to four points. Click away from any existing points to create a new one, and click a point and drag it to change the speedbrake’s geometry. Note that the maximum width of the speedbrake geometry box here is determined by the “speedbrake max size” field.

After creating at least a rough model of the speedbrake’s shape, you can position it on the aircraft and set its extended and retracted angles.

To begin positioning a speedbrake, you can set the standard location controls, labeled “arms” in Plane Maker, and 2 in Figure 3.22. These are presented here in longitudinal-lateral-vertical order, from left to right. For information on using these controls, see the section “How Positions Are Set in Plane Maker” at the beginning of this chapter.

Next is its “direction of extension,” located to the right of the max size control and labeled 3 in Figure 3.22. A zero angle makes the speedbrake point straight up, while an 180 degrees makes it point down.

Beneath that are the speedbrake’s extended and retracted angles, labeled 4 in Figure 3.22. Positive values here will cause the speedbrake to hinge upward, while negative values cause it to hinge downward.

The final settings in each speedbrake’s box (labeled 6 in Figure 3.22) are related to its paint textures. Information on working with the paint is found in Chapter 8, in the section “Creating a Basic Paint Job.”

Customizing a Wing’s Pieces (for Incidence, Size and Position)

In the Element Specs box of the Wing window is the piece incidence setting, highlighted in blue in Figure 3.19. This sets the upward angling (or incidence) of each piece, in degrees. This allows you to warp a wing section to point up or down.

Using the checkbox labeled “customize chords,” you can change the width of the wing section from its leading edge to its trailing edge (that is, its chord length) for each piece. Pieces are modified just like when adding a control surface to a piece; the boxes on the far left correspond to the portion of the wing section that is closest to the fuselage, while the boxes on the far right correspond to the portions farthest from the fuselage.

Figure 3.23: Customizing an aircraft’s chord size and position

Normally, Plane Maker calculates the chord length of each piece (again, the distance from its leading to its trailing edge) by interpolating between the root chord and the tip chord, which you set in this tab’s Foil Specs box. Using the “Rib chord ratio” setting, though, you can modify the width of each piece. The Plane Maker-calculated value for the chord length is multiplied by the ratio you set here to get the actual width of this piece.

For instance, if Plane Maker saw that the chord length should be 5 feet at the center of a given piece, and you used a chord ratio of 2, the center would end up with a 10-foot chord length. Likewise, if you had chosen a ratio of 0.5, it would end up with a chord length of 2.5 feet.

Finally, the “Rib chord offset” setting, seen in Figure 3.23, determines how far forward or back a given piece gets shifted. Positive values will push the wing section behind the reference point, while negative values will push it forward of the reference point. This is specified as a ratio of the Plane Maker-calculated chord length. Thus, with a calculated chord length of 5 feet, and a chord offset of 0.5, a given piece will be pushed farther behind the reference point by 2.5 feet.

Use the above settings to customize the fine details of a wing section’s size and shape.

Setting a Wing’s Airfoils

Creating a wing in the standard Wings dialog box specifies only the wing’s size, location, and the direction it’s pointing—it does not specify what shape the wing has. Is it thin along the trailing edge and fat along the leading edge? Maybe it is fat along both edges, or maybe it is fat in the middle and thin at the edges. To tell Plane Maker just what (cross-sectional) shape the wing has, we need the Airfoil dialog box, which is launched from the Expert menu.

Each wing section can have three different airfoils set for it—one airfoil for the root, one for the middle, and one for the tip. These airfoil shapes are then blended together linearly.

The airfoil shapes themselves must be created using the separate Airfoil Maker application, which, like Plane Maker, is included in the X‑Plane installation folder. X‑Plane does not look at the shape of the wing and then decide how much lift, drag, etc. the foil will put out—X-Plane is not a computational fluid dynamics program. Instead, X‑Plane uses pre-defined airfoils that list the performance of any airfoil (lift, drag, moment) to predict how the plane will fly with that foil. For information on using Airfoil Maker to create these airfoils with predefined performance, see the Airfoil Maker manual.

To apply an airfoil shape to a wing after the wing has been created, open the Expert menu and click Airfoils. In the Airfoils dialog box, go to the Wings tab. Here, you can set what airfoil will be used in three sections of each wing: at the root, the middle, and the tip, as seen in Figure 3.24.

Figure 3.24: The wings airfoils window

Select or change the airfoil by clicking the gray box, then navigating through the file picker window to your file. X-Plane’s default airfoils are found in the “X-Plane 11\Airfoils” directory. Once set, adjust the exact positioning on the wing by using the fields to the left. “Use root foil inboard” sets how far from the root the airfoil extends. “Use mid foil outboard” and “use mid foil inboard” will apply the middle airfoil starting and ending from the points you set, respectively. Finally, “use tip foil outboard” field will use the airfoil set in the tip field from that point outward to the tip of the wing. X‑Plane will interpolate any gaps between the values you set for the mid foil and the root and tip values.

The following page may be useful in determining what airfoils to use in your wing (assuming you’re modeling an aircraft that is already in production):

Making a Wing Movable

Just like in the real world, wings in X‑Plane do not have to be static. They can be swept forward or back, they can be angled up or down, and they can even be retracted.

Figure 3.25: The parameters to make a wing movable in the Airfoils dialog box

In the Airfoils dialog box (launched from the Expert menu), each wing has a group of four checkboxes, as seen in Figure 3.25.

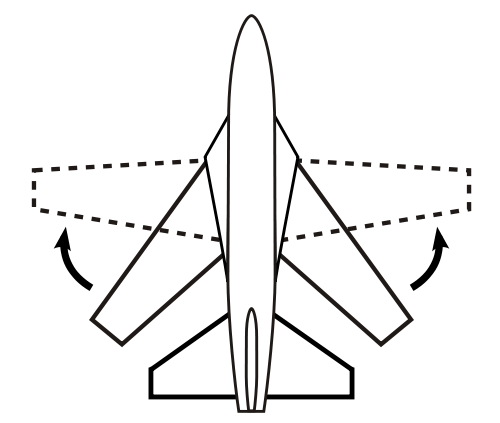

Setting Variable Wing Sweep

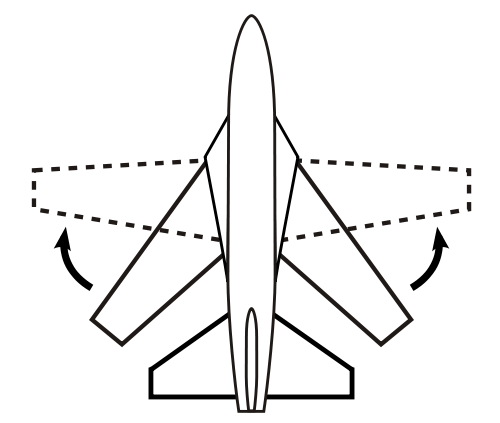

Checking the first box in Figure 3.25, labeled “variable sweep,” will allow you to set the maximum wing sweep in degrees. Positive values here will allow the wing to angle further behind the reference point, while negative values will allow it to angle forward of the reference point. This variable sweep is illustrated in Figure 3.26.

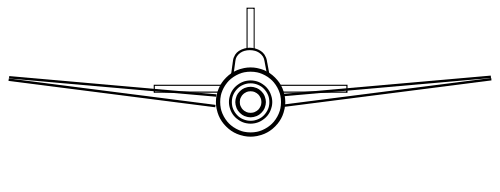

Figure 3.26: Variable wing sweep illustrated (thanks to Wikimedia Commons user [SteelPillow](http://commons.wikimedia.org/wiki/User:Steelpillow) for the image)

Wing sweep is measured in degrees of sweep along the 25% chord (that is, along the line 25% of the way behind the leading edge of the wing). Note that you set the maximum sweep here; the minimum sweep is set as the default wing sweep, found in the Wings dialog box (opened from the Standard menu).

Variable wing sweep is useful in aircraft that approach or exceed the speed of sound, but which must also perform well at low speeds. As your speed increases toward Mach 1, a wing that meets the air head-on generates more and more drag. Variable sweep wings are most popular in military aircraft (like the B-1 Lancer and the F-14 Tomcat).

To use a variable sweep in X-Plane, you can add a sweep control to the instrument panel. Alternatively, you could assign a button or key to the “vector sweep aft” and “vector sweep forward” controls in the Joystick and Equipment dialog box.

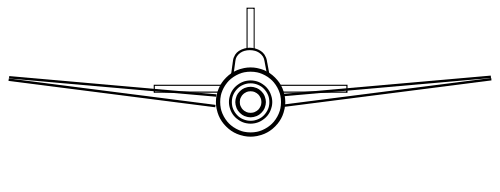

Setting Variable Wing Dihedral

Checking the box labeled “variable dihedral” in the Airfoils dialog box (seen in Figure 3.25) will allow you to change the angle of the wing above or below the horizontal plane in flight. This is illustrated in Figure 3.27.

Entering a positive value here corresponds to an angle upward from horizontal (like the wings in Figure 3.27). Likewise, entering a negative value will correspond to a downward angle. A relatively high dihedral angle will increase the “dihedral effect” on the wings—that is, the wings' tendency to stabilize and level the aircraft in a roll.

Figure 3.27: Wing dihedral, the upward angle of the wings, illustrated (thanks to Wikimedia Commons user [Steelpillow](http://commons.wikimedia.org/wiki/User:Steelpillow) for the image)

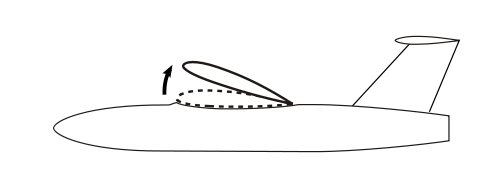

Setting Variable Wing Incidence

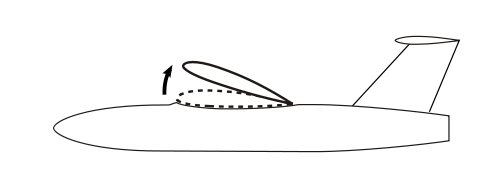

Checking the box labeled “variable incidence” in the Airfoils dialog box (seen in Figure 3.25) will allow you to change the wing’s angle of attack in flight. This angle, known as the angle of incidence, is illustrated in Figure 3.28.

Enter the maximum incidence here, in degrees. Positive values correspond to an upward angle of the wing when viewing the aircraft from the side, while negative values correspond to a downward angle.

Figure 3.28: Variable wing incidence illustrated on a high-wing plane (thanks to Wikimedia Commons user [Steelpillow](http://commons.wikimedia.org/wiki/User:Steelpillow) for the image)

A small positive angle of incidence is used in most aircraft in order to keep the fuselage horizontal when the aircraft is cruising. Thus, changing the angle of incidence in flight will also change the angle of the fuselage as the aircraft flies.

Making a Wing Retractable

The final dynamic wing checkbox in the Airfoils menu is labeled “retractable” (as seen in Figure 3.25). Check this box, then set the maximum retraction as a ratio of the wing section’s semi length. For instance, if the wing section was 10 feet long and you set the max retraction ratio at 0.5, the section would retract up to 5 feet into the fuselage.

Adding More Wing Sections

In some cases, the four “regular” wing sections, two vertical stabilizer sections, and single horizontal stabilizer section found in the Wings dialog box are not enough to accurately model an aircraft’s wings. In this case, you can add more wing sections by launching the Misc Wings 1 or 2 dialog box from the Standard menu.

Wing sections here are added and modified just like in the regular Wings dialog box, with one exception: wing sections are not mirrored across the body. Instead, when you need a section duplicated on each side of the craft, you’ll need to create the wing section as it should be on the right side of the craft, copy that section to a new Init Wing tab, and there click the radio button labeled “(LEFT wing)” found in the Foil Specs box, as shown in Figure 3.29.

Figure 3.29: The radio button to add a wing section on the left side of the aircraft

Shaping the Tail

A typical aircraft tail is made up of a horizontal stabilizer and a vertical stabilizer. With this in mind, there are two vertical stabilizer sections and a single horizontal stabilizer wing section available in the Wings dialog box (launched from the Standard menu). These wing sections are shaped just like a standard wing, as described in the previous section, “Shaping the Wings.”

If you need more wing sections than are present in the Wings dialog box, you can add more sections using the Misc Wings 1 & 2 dialog boxes, as described in the section “Adding More Wing Sections” above.

Shaping the Landing Gear

The landing gear is created using the Landing Gear dialog box, which is opened from the Standard menu.

Setting the Gear’s Type, Size, and Position

Landing gears come in a variety of configurations, ranging from simple metal skids, to a single wheel, to groups of many wheels. Any landing gear needs to have its position on the aircraft specified, and if the gear is retractable, it must have a retracted position that is different from its extended position. The gear also must have a size—both its tire size and its strut length.

These properties of the gear are defined using the first tab of the Landing Gear dialog box, labeled Gear Loc (that is, gear location). In this tab, you can create up to ten different gears. Each gear has a column dedicated to setting its properties; Figure 3.30 highlights a single gear’s column.

Figure 3.30: A single landing gear’s column

Let’s walk through the settings for each gear.

Note: If you are using a retractable gear, you will want to do two things before trying to specify the gear’s properties. First, check the box labeled “retracts” at the bottom of the column. Then, close the Landing Gear dialog box and click “Show with still/moving controls,” found in the Special menu. This will animate the gear as you work on it, so you can see just how far it extends and retracts.

At the top of the Gear Loc tab is the gear type parameter. Click the drop-down button and select from a wide array of wheel (or skid) configurations. A lateral wheel configuration arranges the wheels side-by-side, while a truck configuration arranges them in rows. A “long” wheel configuration arranges them one in front of another. Finally, note that any gears you will not be using should have a type of “none” selected.

Next, beneath the gear type parameter are the three standard positional controls. These are, in order, the longitudinal arm, the lateral arm, and the vertical arm. For information on using these position controls, see the “Fundamental Concepts” section at the beginning of this chapter, which discusses the reference point and its use in determining locations on the aircraft.

Following the standard position controls are the parameters determining the gear’s angle when extended and retracted. There is a “gear extended” pair of parameters, and there is a “gear retracted” pair. Each of the angles measures the gear strut’s deviation in degrees from being perfectly vertical, lined up with the reference point.

In the case of the longitudinal angles, the parameters measure how far the gear is angled to the fore of the reference point. Thus, if the gear needed to angle toward the aft of the reference point, you would use a negative number here. Positive 90 degrees will angle the gear forward and perfectly horizontal, while negative 90 degrees will angle it backward and horizontal.

In the case of the lateral angles, the parameters measure how far the gear’s strut is angled to the right of the reference point. Thus, if the gear needed to angle to the left, you would use a negative number. Positive 90 degrees will angle the gear to the right to be horizontal.

Following the gear’s extended and retracted angles is the eagle-claw angle & leg length parameters, set side by side on the same line. Leg length sets the length of the strut, or the “leg” of the gear, when it is extended. (For many aircraft, the extended and retracted length will be the same; some, though, may compress the gear when retracting it.)

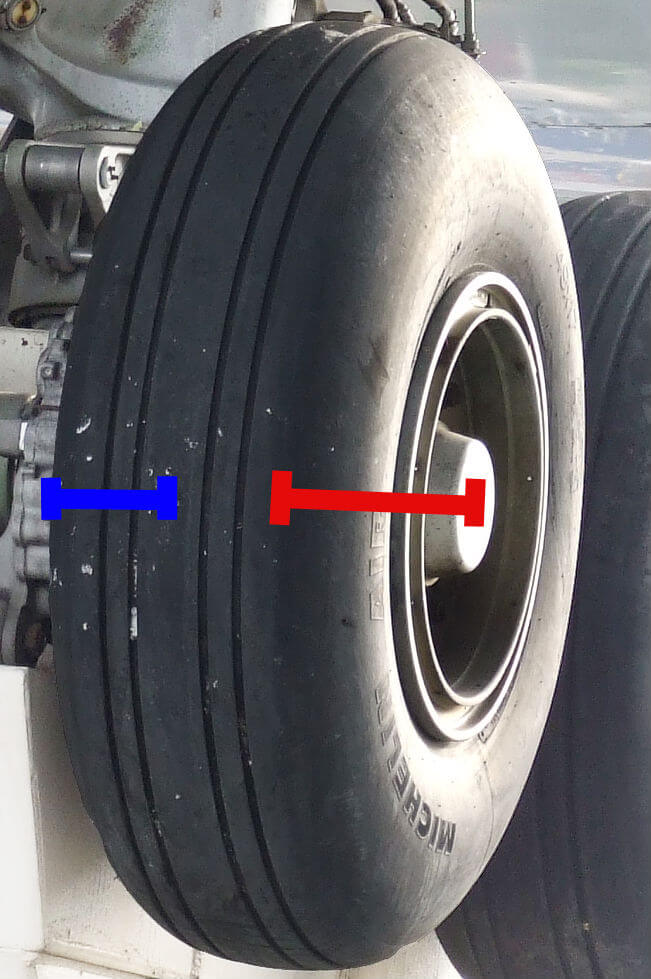

Next are the two parameters controlling the tire size. Each of the tires on a given gear must be the same size. The tire radius is the length from the outer edge to the center of the tire, when viewing the aircraft from the side. Don’t confuse this with the diameter, which is the length from one side to the other when crossing through the tire’s center. The tire semi-width is half the width of the tire, when viewing the aircraft head-on. In Figure 3.31, the tire radius is shown in red, while its semi width is shown in blue.

Figure 3.31: The tire radius (red) and semi width (blue); thanks to Wikimedia Commons user [Kozuch](http://commons.wikimedia.org/wiki/User:Kozuch) for the photo.

The next controls are for the amount the nosewheel or tailwheel of the aircraft can steer. Enter zero for wheels that do not steer at all. For aircraft with steering nosewheels, see the section “Customizing Wheels and Steering” below.

Next are the “retract axis” and “strut compress” controls (in left to right order, respectively). The first parameter sets the amount, in degrees, that the wheel rotates around its own axis when it is retracted. Note that its axis is effectively the gear’s strut. Positive numbers here correspond to a clockwise rotation when viewed from the aircraft’s underside.

The strut compression parameter sets the amount, in feet, that the strut collapses on itself when the gear is retracted. In some aircraft, like the F-4 Phantom II, the gear compresses on itself like this to save space.

Next, beneath the retract axis and strut compression parameters is the “cycle time.” This is the time, in seconds, that it takes for the gear to go from fully extended to fully retracted, and vice versa.

Finally, at the bottom of the dialog box are three checkboxes. The first, “retracts,” toggles whether the gear is retractable or not. The box below that should be checked for any gear that is used for braking. Check the “castors” box if the wheel castors freely all the time.

Using the parameters above, you can create a basic gear with wheels and a simple strut. If the gear is retractable, you will still need to set a few more of its properties, as described in the following section, “Finishing Retractable Gears.” To fine-tune a gear’s steering properties, see the section “Customizing Wheels and Steering” below.

Finishing Retractable Gears

When creating a retractable gear, you will need to specify a few properties in addition to the size, position, and type. Many of these are located in the Landing Gear dialog’s Gear Data tab.

In the top section, “Gear Retraction and Nosewheel Steering,” is the “gear can retract on ground” checkbox. With this unchecked, the aircraft will sense that the gear is bearing the weight of the craft when it is on the ground and will thus not allow you to retract the gear. This is useful for preventing damage to the aircraft. Check the box directly below for seaplanes which have no landing gear and must take off and land on the water.

At the bottom of the right side of the section is the “additional gear flatplate area.” When the gear is extended, X‑Plane will automatically add drag based on the frontal area of the struts, the wheels, and the doors in its flight model. However, any time a gear door opens up to let a wheel out, it also opens the gear wells. These wells disrupt the airflow over the craft, so you should enter the frontal area of the inside of this well here so that X‑Plane can calculate the drag generated by it.

Gear Warnings

If a landing gear is retractable, there will often be a speed above which it is not safe to have the gear extended (the maximum landing gear extended speed, Vle) and a speed above which it is not safe to extend or retract the gear (the maximum landing gear operating speed, Vlo).

To have X‑Plane prevent the gear from extending at speeds above these limits, even if the gear handle is lowered, open the Special Equipment dialog box from the Expert menu. There, in the Equipment Options section, check the first box on the left for “gear extend protect.”

Additional gear warnings can be configured in the Systems dialog, chosen from under the Standard menu. In the “Gear Warnings” box at the bottom of the screen, check the box in the far right column labeled “gear warning horn equipped” to have X‑Plane play a warning noise if you do not lower the landing gear when you reduce power. The warning will also sound when the value in “activate if speed below” is met. Once below the activation speed, the values in the throttle and flap fields will also trigger the warning sound.

Customizing Wheels and Steering

Using the preceding sections, you can build a landing gear with the right wheel configuration, the right position, and even the right retraction characteristics. What we haven’t touched on yet is the steering characteristics of the gear, as well as the properties of the wheels themselves.

There are two “nosewheel steering” parameters on the Gear Location tab. These control how far, in degrees, the wheels responsible for steering can deflect while going slowly.

Figure 3.32: The steering and nosewheel settings

If the aircraft does not use the typical nosewheel steering configuration and instead uses free caster wheels which are controlled using differential braking, set this parameter to zero. (Note that nosewheel steering is a general term for steering by moving the wheels—it applies to taildraggers that steer with the tail wheel also.)

Figure 3.33: The landing gear friction coefficients

Another important set of parameters impacting the aircraft’s ground steering is the landing gear’s coefficients of friction. These parameters, found in the bottom of the Gear Data tab, are shown in Figure 3.33. The rolling coefficient of friction (the box on the left) controls how much friction is produced by the weight of the airplane on the wheels when rolling on pavement. A value of 0.025 is typical, indicating that the drag of the wheels on the pavement is 0.025 times the weight of the aircraft when rolling. X‑Plane will modify this value automatically when rolling on grass strips or off a runway.

The maximum coefficient of friction, the box on the right in Figure 3.33, controls the maximum amount of friction that the tires can generate, both by braking and from side loads.

Figure 3.34: The wheel and tire geometry settings

The final gear parameters we will consider here are those controlling the wheel and tire geometry. Figure 3.34 shows these controls, which are found in the middle of the Gear Data tab. The “wheel lateral separation” specifies the distance between wheels in a side-by-side configuration. This is measured in half-tire widths, from one tire’s middle to the other’s. Thus, a lateral separation ratio of 2 here puts the tires touching each other side by side.

The corresponding “wheel longitudinal separation” parameter sets the distance between wheels in an inline configuration. This is measured in tire radii (the distance from the center of the tire to its edge), from one tire’s middle to the other’s. Thus, a ratio of 2 here puts the tires touching along their edges as they rotate.

Designing Wheel Fairings and Skids

For each of your gears created in the Gear Loc tab of the Landing Gear dialog box, you can choose to add a streamlined fairing. Sometimes known as a wheel pant or spat, a fairing is designed to reduce the drag generated by a landing gear by presenting a streamlined surface for the air to interact with.

To add a fairing, open the Bodies screen from the Standard menu. Wheel fairings are simply bodies, and can be attached to any given gear by selecting it in the “attach to gear” drop down. Fairings are modeled just like the fuselage and the miscellaneous bodies; there is a Section, Top/Bottom, and Front/Back tab for each fairing. See the “Shaping the Fuselage” for information on using these tabs.

Adding Other Surfaces and Bodies

In the previous sections, we’ve talked about creating a fuselage, a tail, wings, and a landing gear. What about everything else?

Extra bodies like external fuel tanks, engine pylons, engine nacelles, and slung loads are modeled in the Bodies dialog box, described in the section “Adding Other Bodies to the Fuselage.”

For information on adding weapons and slung loads to an aircraft, see the section “Creating and Adding Weapons” in Chapter 7.

For information on engine pylons and engine nacelles, read on to the following sections of the manual.

Adding Engine Nacelles

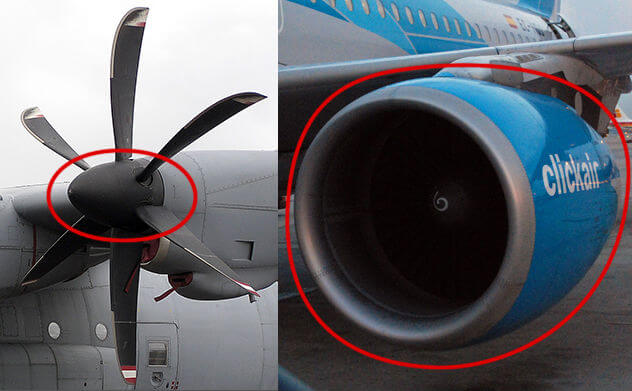

An engine in X‑Plane is primarily a point from which thrust is generated: propellers are no more than spinning, thrust-producing blades, jet engines are no more than points from which thrust is produced, and so on. To create the body of the engine (like the tip of the propeller or the body of a jet engine), you must add an engine nacelle. Figure 3.35 shows the parts of a propeller and a jet engine which would be modeled as nacelles in Plane Maker. Like every surface in X-Plane, these nacelles will have both visual and aerodynamic consequences. Note that it only really makes sense to create the nacelles after you have created the engines themselves, as described in the section “Creating the Engines” of Chapter 4.

The Bodies dialogue box is used to add engine nacelles. Bodies here are created just like the fuselage and the miscellaneous bodies; for more information, see the sections “Shaping the Fuselage” and “Adding Other Bodies to the Fuselage” previously in this chapter.

Figure 3.35: Parts of the engines modeled as nacelles (thanks to Wikimedia Commons user [Delatorre](http://commons.wikimedia.org/wiki/User:Delatorre) for the jet engine photo)

Once the nacelle body has been created, select which engine it attaches to from the “attach to engine” drop down.

Figure 3.36: The "attach to engine" drop down

Adding Engine Pylons

Engine pylons are the hardpoints of an aircraft designed to have engines mounted to them. Modeling a pylon is very similar to modeling a wing—a pylon just ends up being a short, stubby, oddly shaped wing, which might itself be attached to a real wing. In light of this, pylons are added in the Misc Wings 1 screen, found under the Standard menu. For information on using the standard wing controls, see the section “Shaping the Wings” above. Note that if you use all the tabs in Misc Wings 1, you can move on to Misc Wings 2, enabling you to model up to 36 different wings and wing-like bodies.

Figure 3.37: An Airbus A380's engine pylon (thanks to Wikimedia Commons user [David.Monniaux](http://commons.wikimedia.org/wiki/User:David.Monniaux) for the photo)

To apply a pylon design to a certain wing, select the wing portion from the drop down at the top of that pylon’s tab. These sections are labeled as they are in the tabs of the Wings and Misc Wings 1 & 2 dialog boxes.

Setting the Location of the Tow Hook, Winching Hooks, Boarding Door, and Refueling Port

A few miscellaneous features of the aircraft’s body are set up using the Viewpoint dialog box, launched from the Standard menu. In the Viewpoint dialog box’s Dock Ports tab, the position of the aircraft’s tow hook, winching hook, refueling port, and boarding door can be specified using standard position controls, as described in the “Fundamental Concepts” section at the beginning of this chapter.

Figure 3.38: The Dock Ports tab of the Viewpoint dialog box

The position of these features of the body will only be visible when using the wireframe view (toggled using the spacebar). There, they will be represented as large black dots, just like the point representing the aircraft’s center of gravity.

Note that both the winching hook and the tow hook must be centered laterally along the aircraft’s body, so they do not have a “lat arm” parameter.

In addition, you can set what ground service vehicles, such as food, baggage, or fuel trucks, will service the aircraft in this screen.

Working with the Aircraft’s Systems

An aircraft’s systems include electrical, hydraulic, fuel, avionics, flight control, and propulsion sub-systems. In addition to influencing the flight model as appropriate, these systems can be set to fail in X-Plane, allowing pilots to practice dealing with contingencies.

Creating the Engines

The aircraft’s engine, along with any related propellers, thrusters, and so on constitute its propulsion sub-system.